Quality and Certification

Super Nut: a professional multistage cold formed metallic fastener manufacturer, providing comprehensive testing and international certification

Super Nut is committed to our quality management, upholding the service of excellent quality and profession in the production of cold formed parts, including Blind Rivet Nuts.

Our management system conformity is certified per ISO 9001:2015 and IATF 16949:2016, and we are always under continuous improvement to become your most reliable partner in providing top-tier cold formed solutions.

Our quality instruments include Digimatic Caliper, Digimatic Micrometer, Digimatic Indicator, Dial Thickness Gauge, Thread gauge (Plug & Ring), Pin Gauge, Rivet Nut Setter / Gun (spin-spin and spin-pull), Gauge Blocks, Universal Testing Machine, KEYENCE Image Dimension Measurement System (IM-6120), Optical Sorting Machine. We can provide inspection reports and other documents according to order requirements, and PPAP documents and IMDS reports can also be provided based on customer needs to meet various quality requirements.

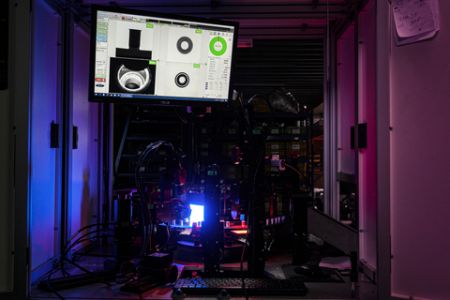

Universal Testing Machine: To acquire pull-out, push-out, spin-out, torque-out / torque to turn, proof load, tensile strength, compression strength and shear strength.

KEYENCE Image Dimension Measurement System (IM-6120): Exterior dimensions' measurement with ability to measure 99 features simultaneously within only a few seconds.

Optical Sorting Machine: Sorting parts with criteria of exterior dimension specs (head diameter, body diameter, length), presence of thread, mixture of foreign matter, roundness, and surface damage (depends on features).

As a multistage cold formed metallic fastener manufacturer, Super Nut adheres to the business philosophy of "Service First, Quality Priority," dedicated to producing products that meet the highest standards of safety, durability, and stability. Through international certifications such as "ISO 9001" and "IATF 16949", we strengthen product quality and production stability, enhancing and increasing our competitive advantage. We look forward to creating a win-win market with our customers.

Gallery

- Optical Sorting Machine

- Universal Testing Machine / IM-6120 / Cutting Machine

- Universal Testing Machine

- KEYENCE Image Dimension Measurement System (IM-6120)

- Automatic Metallographic Cutting Machine

- Rivet Nut Setter / Gun (spin-spin and spin-pull)

- Digimatic Caliper

- Digimatic Indicator

- Micrometer